Introduction

You can walk into any home improvement store and find all kinds of tarps on the shelf. They all seem very similar at first glance. Tarps are large sheets used as protective barriers made from a flexible material.

It doesn't get more complex than that, right?

Well, despite sharing similar designs and colors, there are variations you should pay attention to.

You can see the thickness, duty specification and material type by grabbing and reading one tarp package off the shelf. But some tarps are manufactured to provide a specific function that goes beyond conventional.

For example, insulated tarps (sometimes known as insulated blankets) pack a different sort of punch that a conventional tarp doesn't.

This article is your guide to illustrating precisely what that "punch" is and how insulated tarps stand out from the field.

** This article is provided for informational purposes only.

IN THIS ARTICLE YOU WILL LEARN...

INSULATED TARPS DEFINITION AND DESCRIPTION

What are insulated tarps?

A very straightforward definition for insulated tarps is that they’re large sheets of material designed to help maintain the temperature of the environment it is protecting.

In colder climate regions, insulated tarps serve as a barrier or winter enclosure for construction projects or industrial maintenance. Their insulating properties make them ideal for concrete curing applications as well.

One or multiple layers of thermal insulation foam are sandwiched between tarp fabric to give the tarp its insulating properties. Substituting foam for other insulative materials, such as tightly-packed polyester fibers, can be done too.

What’s their purpose?

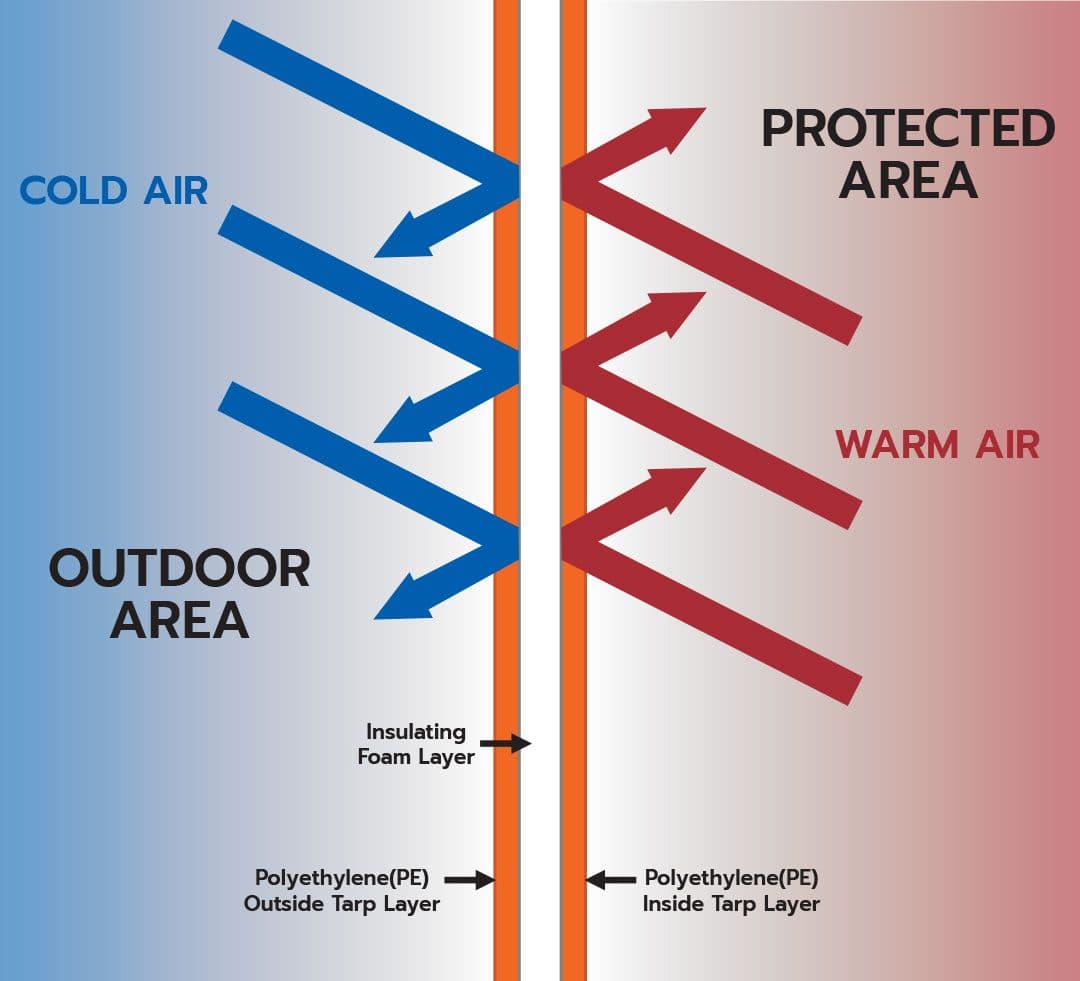

Insulated tarps work as an “air barrier” of sorts. Warm air is contained and doesn’t pass through the insulating foam escaping to the outside. Similarly, cold air doesn’t seep through from the outside into the area being kept warm.

It’s essentially the same idea as a blanket you would use on your bed. The blanket prevents your body heat from escaping, keeping you warm. But the blanket also prevents cold air or drafts from passing through to contact your skin.

Some insulated tarps are even designed to withstand medium to high winds. The stronger the wind, the faster it will push the heat out of an unprotected area. Insulated tarps designed for wind resistance help stop this effect and keep the warmth where it needs to be.

Insulated tarps can also be water, UV and mildew resistant. This enables the tarp to hold up to long-term exposure to the elements.

Imagine being a construction worker, trying to complete your tasks in an office building project. The construction of the final walls and windows needs to be completed, so you're trying to get your work done while exposed to the elements.

That might not seem too difficult at first glance, but let's raise the stakes…

It also happens to be January in Winnipeg and the temperature is at a despicable -40°C. For readers that use Fahrenheit, it's also -40°F, so there's no good way of looking at how cold that is. "Calling in sick" to avoid the weather isn't a serious option when construction projects are on a tight deadline, but no one wants to work in that cold. However, what if you could work on an exposed site in these conditions and be assured you won't experience frostbite within minutes?

This is where insulated tarps become a saving grace. They're flexible in design, affordable and provide the necessary protection when temperature and wind become a workplace hazard. As mentioned, they keep the cold air on the outside away from the personnel and equipment inside, as the insulated tarp is the barrier that contains the warm air.

Many crews also use industrial heaters inside the work area to generate heat. When insulated blankets are in place, this will keep the work area warm so personnel can complete their work without turning into a popsicle.

Material and Tarp Selection

Standard tarps can be made up of many different materials, such as canvas, vinyl and various forms of poly plastics (ie. polyethylene, polypropylene, polyurethane, etc.), among others.

However, it's safe to say that most insulated tarps on the market are made from poly plastics (usually polyethylene) with a foam or fabric-insulating barrier in between. Think of an insulated tarp's composition as a sandwich, with two layers of tarp as the bread and the insulating membrane as the meat and cheese.

The layering of materials creates a thicker tarp and an overall "bulkier" appearance than standard tarps. You can also purchase heavy-duty canvas or custom vinyl tarp assemblies, which boast moisture, UV, mold and all-weather resistance. Although these types of tarps make a terrific barrier wall, it's important not to confuse "heavy duty" and "all-weather" with "insulated." If the purpose is to insulate a space and retain heat, these other options won't cut it.

A custom-cut heavy-duty vinyl option is considerably more expensive than a standard 12' x 24' insulated tarp. A good analogy for this would be buying a Ferrari for an off-road race. The Ferrari would be a great option on smooth pavement but a nightmare on muddy, uneven, rocky terrain.

If the space size is an issue, you can use multiple tarps to accommodate a bigger space or even fold the tarp to accommodate a smaller one. Ultimately, why would you want to spend thousands on a product whose intended use is not insulation when you could've spent a couple hundred dollars to get the desired results?

The Mind-blowing Ability and Importance of Closed Cell Foam Insulation

Insulated tarps typically use closed-cell foam in between the tarp layers. "Closed cell" means air and moisture can't permeate the foam, as opposed to "open cell" foams, which are exposed to air and moisture in exchange for softness and flexibility.

Closed-cell foams are higher in density, which means their resistance to heat flow is much better. They also act as a vapor barrier, which adds to the insulated tarp's resistance to mold and mildew.

Some fibrous materials, like polyester or fiberglass, can also be used, but a closed-cell foam membrane adapts better to a confined space like an insulated tarp. Closed-cell foams also have higher rigidity compared to open-cell foams and insulating fibers. A higher rigidity helps maintain the structural integrity of the tarp for extended periods while still being able to roll up or fold it for storage when not in use.

Other Features

Grommets

Like most other tarps, insulated blankets come with grommets. A grommet is a flexible loop usually made from metal but can also be fabricated from materials like rubber or polycarbonate. Most insulated tarps use traditional brass or nickel-plated grommets situated in the corners and sometimes along the tarp's edges.

Grommets serve as a fastening, support, or reinforcement point. These eyelets protect the tarp's opening or even insulate the tarp material from the object passing through it. Depending on the insulated tarp, you may have grommets only in the four corners and none along the side edges. Insulated tarps intended for concrete curing use this type of grommet orientation.

Insulated tarps used for hoarding or general purposes are made with grommets in the corners and along the sides of the tarp. Grommet spacing ranges anywhere from 18" to 48". Bungees, ropes, or other fasteners secure the tarp to a structure or hook-up point and can be adjusted to fit specific areas.

Color

You may have heard about color code guides for determining different tarp uses. These codes can give good information on tarp usage (ie. light duty vs heavy-duty), but they should still be taken with a grain of salt when it comes to certain colors for specific uses. One standard chart for conventional tarps from the US breaks it down like this:

Blue — (0.12mm - 0.15mm thick) Light duty tarps. Use as a floor covering, temporary rain tarp or other simple protection use.

Yellow — (0.18mm - 0.20mm thick) Light duty tarps. Thicker than blue tarps and can handle a little more strenuous work.

Green — (0.23mm - 0.25mm thick) Medium duty tarps. These tarps are abrasion resistant and suitable for all manner of general purpose work.

Silver — (0.28mm - 0.30mm thick) Heavy-duty tarps. They can be used for commercial purposes, including construction, demolition and even roof tarping.

Brown — (0.41mm +) Super heavy-duty tarps. These can be 25% thicker than heavy-duty tarps and can be used for vehicles transporting rocks, dirt or other materials. They also offer protection for buildings.

Always remember that the manufacturer will determine which colors will be fabricated for different types of tarps. A simple Google search will show that one manufacturer makes a blue-colored medium-duty tarp, and another makes a green construction-grade heavy-duty tarp. Many manufacturers also make orange and white tarps for commercial uses, and even custom colors or patterns like camouflage are manufactured too.

These charts go out the window completely when it comes to insulated tarps. It’s important to understand that manufacturers make insulated tarps primarily for industrial and commercial uses. Customization of color or adding a company logo are options, but most manufacturers produce safety orange or black for insulated tarps.

These are the most common insulated tarp colors due to their ability to allow some light to pass through and their high visibility appearance. These features are excellent on a construction site where jobsite functionality and work safety are always top priorities.

Sizes

Insulated tarps can come in various sizes, much like standard tarps. The standard length and width are in increments of 2, depending on the manufacturer. You can easily find different sizes from different manufacturers of insulated tarps in North America. The following five brands were all found with the search keyword: “insulated tarp manufacturers.”

Insulated Tarp Manufacturer Standard Sizes Table

This table shows that finding the proper manufacturer is essential, but most brands offer similar tarp sizes. Some brands like B & C offer a thinner 6’ option, while others like Brand E have longer 30’ and 50’ options.

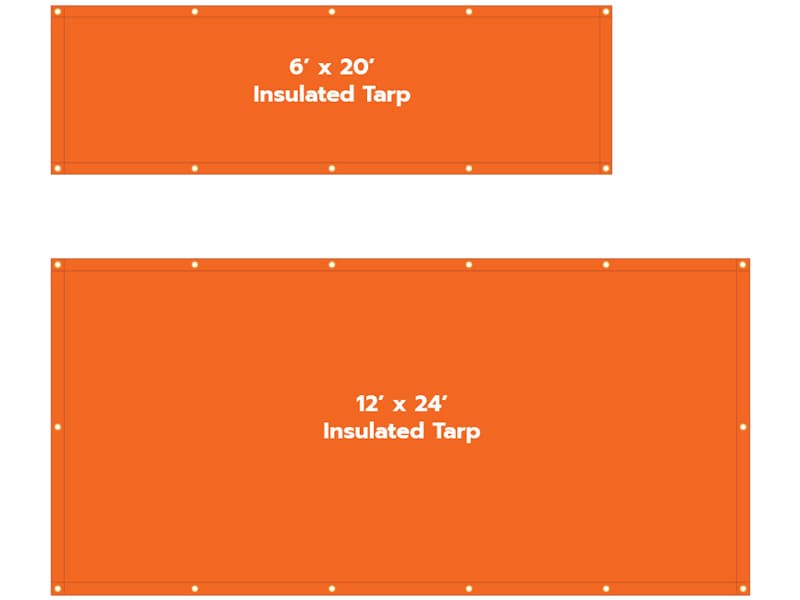

Standard Insulated Tarp Sizes

It's common to see standard sizes for insulated tarps between 6' to 12' wide and 20' to 24' long. These values are a general average; as mentioned, every manufacturer is different. The above diagram demonstrates the small and large ends of that range to give a broad view of the typical tarp sizes and shapes.

Returning to the manufacturer table, you'd also notice that all brands offer custom sizing as an alternative to standard sizes. A 6' x 20' or a 12' x 24' tarp might not fit the job requirement.

Let's say you're providing a roof over a long construction trench. When you do the measurements, the trench is only 5' wide but over 70' long. It's almost a guarantee there won't be a standard size 5' x 70' tarp anywhere. However, most manufacturers anticipate custom jobs happening in everyday situations. A custom-cut tarp to fit the exact measurements would only be a phone call away from manufacturing with these five brands.

Even though you can fabricate a custom-insulated tarp to whatever measurement is desired, it's important to note that anything custom will likely be more expensive. Custom jobs can also take longer as manufacturers must slot them in amidst their regular production schedule.

Another size feature with insulated tarps is thickness. There can be multiple layers of foam or insulating properties inside the tarp ranging from ¼" to even 1" insulated tarps. Concrete curing blankets are thicker, while general purpose or hoarding tarps tend to be thinner or have fewer layers.

Hoarding Applications and Insulated Tarps

You may be thinking, "What is hoarding?" Like the pack rat you might know who doesn't throw anything away, a "hoarding" application doesn't want to "throw away" heat. Insulated tarps are the go-to equipment when wrapping up an exposed area to retain heat.

Remember the analogy from earlier about working outside in Winnipeg during the winter? That specific example is where insulated tarps come into play for hoarding applications. Whether it's an industrial worksite or making a temporary shelter for ice fishing, temperatures outside can plummet to extremely frigid conditions in Canada and the northern United States. Understandably this can make working conditions or trying to tie a fishing line with numb fingers uncomfortable, to say the least.

Insulated tarps can be unfurled and tied over an open gap or frame to provide shelter and retain heat. Bungees, ropes, or hooks go through the grommets to secure the tarp. Besides blocking wind, rain, snow, and sleet on the outside, it keeps warm air inside.

Many job sites will often utilize large commercial heaters to pump hot air via a duct system to the area. A portable gas or electric heater works in smaller personal examples like the ice fishing shelter. Regardless of the heat source, insulated tarps retain that heat so crews can operate efficiently and on schedule.

Concrete Curing Applications

Finishing concrete can be grueling work, and the process can be pretty intricate. Attention to detail is essential and concrete contractors know that precision is vital to ensure concrete sets properly. You know by now that insulated tarps retain heat and block cold air from passing through. This is invaluable in concrete curing, as cold temperatures can compromise a curing slab and cause damage like scaling or cracking.

For concrete to properly cure, it's crucial that the prep work is finished and suitable for the pour. Afterward, "finishing" the top layer of the concrete is necessary for curing to begin. In many ways, it's like baking a cake and decorating it. Measuring ingredients and using an appropriate pan for the batter would be laying out the foundation, including a gravel base, underlayment, rebar grids, forms, etc.

Where insulated tarps come into play is the finishing process.

Much like allowing a cake to cool before removing it from the pan and decorating it, allowing the right amount of time to set and providing just enough moisture on the slab are essential aspects of finishing concrete. However, after the last broom strokes or trowel marks are made on the concrete, there is still the temperature aspect.

Concrete takes time to set. Depending on the job size, it can take 24 to 48 hours or sometimes longer. Ideal curing temperatures are between 50°F - 90°F (10°C - 30°C). If temperatures dip below this range, the chemical reactions in concrete slow down, and you risk the water in the concrete freezing and causing cracks. This will result in a failed finish and costly rework.

If a concrete contractor finishes a section of sidewalk and the temperature dips to 37°F (3°C) overnight, draping the insulated tarp over the top keeps the cool air off the slab surface and enables proper curing. When concrete cures, it releases heat as an exothermic reaction, acting as a heat source that the insulated tarp will contain.

Insulated tarps for concrete curing tend to have more layers than insulated hoarding tarps for increased heat retention. Concrete blankets have grommets, but only in the corners, as they're typically tied or suspended to any structure or frame, like hoarding tarps are. They're usually laid out over the concrete for their application.

Insulated Tarps and Ground Thawing

Construction companies in Canada and the northern United States often face extremely low temperatures during the winter, making it challenging to pour concrete until warmer weather arrives. Frost settling into the ground further exacerbates the issue. To overcome this challenge, some companies rent ground thawing machines that use a heated solution pumped through a system of hoses laid on the ground. The circulating solution softens the earth enough to allow for concrete pouring.

Insulated tarps are often used in these applications to maximize thawing efficiency by directing the heat toward the ground. The tarps/blankets protect the heated hoses on the unit against the cold weather, ensuring proper thawing and preventing costly repairs.

A Few Thoughts on R-Value

R-value is a rating that indicates how well a layer of insulation resists the flow of heat. You typically see R-value attributed to household insulations and can be referred to as "thermal resistance" instead. Insulations in your housing insulation can vary from R 13 or R 15 in 2x4 walls up to R 60 in attics.

The higher the R-value, the higher the insulating power of a material or assembly of materials. For insulated tarps, R-value is much more of a gray area. First, insulated tarps' R-values are considerably lower than household insulation due to their thinner profile, and household insulations tend to be much thicker.

Second, experiments like C 518 set by ASTM International (formerly known as the American Society for Testing and Materials) show that the R-value for insulated tarps applies under controlled conditions. But even the experiment claims, "1.7 This test method may be used to characterize material properties, which may or may not be representative of actual conditions of use."

Suppose the test conditions don't necessarily represent any real situation the products face during actual use. In that case, it may make one skeptical to think that any R-value rendered from this test can be accurate.

Putting even more question marks on the R-value for insulated tarps, it's interesting to note there's currently no recognized R-Value standard for insulated tarps in Canada or the United States. Some manufacturers claim their tarps have R-values ranging from R 0.8 to R 5, or even higher in some cases. However, it’s important to note that these are estimated values.

All in all, R-Value is something to rely on only a little when considering an insulated tarp. The value stated can fluctuate depending on the environment the tarp is used in, and there's no recognized R-value standard for them.

A Summary of Insulated Tarps

Using insulated tarps significantly contributes to the success of any construction project by protecting crews and equipment from harsh weather conditions. They are lightweight and flexible while still being able to deliver on their insulating properties.

In colder climates, insulated tarps/blankets are essential assets that keep construction work going despite unfavorable weather conditions. All in all, using insulated tarps helps enhance your work environment, improving productivity and the safety of your crews and equipment.

Which part of this guide helped you in your search? Did you learn anything new regarding insulated tarps, hoarding, or concrete curing?

Use this guide and our other articles as a resource to help you determine which product is right for you and keep you and your projects covered.