INTRODUCTION

Safety on a work site is always the top priority, and the area in which the work takes place must be up to standard. Air quality must be one of these priorities when determining a site's suitability. This includes:

Regulating temperature within an area to keep work conditions optimal

Circulating air to provide good ventilation for personnel

Both of these aspects are something achievable through the use of portable temporary ducting. These flexible duct systems are some of the most relied-upon pieces of equipment for getting air from 'A' to 'B' when permanent ducting installations are not available or practical in a given situation.

This article will shed some light on portable temporary ducting and how it flexes in and around the issue of air quality and movement.

** This article is provided for informational purposes only.

DUCTING: A GENERAL UNDERSTANDING

Ducting, from a basic understanding, are passages used in heating, ventilation, and air conditioning (HVAC) to deliver or remove air in residential and commercial capacities.

If you go into the mechanical room in your basement, you can look up and see the sheet metal ducts that run along the ceiling from your furnace. Or if you're at the hockey game in the arena, you can see the large metal vents up in the rafters providing air conditioning and circulation for the thousands of people in attendance.

Regardless of the capacity, airflow is vital to establish good indoor air quality and thermal comfort. A duct system, also called "ductwork," is the highway where the air flows to a designated area from a furnace, heater, air conditioner, etc.

Portable Temporary Ducting Description

Permanent ductwork, like in your house or the hockey arena, can come in various materials, from steel, aluminum, plastic, or even fiberglass.

These are great options for long-term installations, but portable ducting can flex, move, or adjust to be where it's needed.

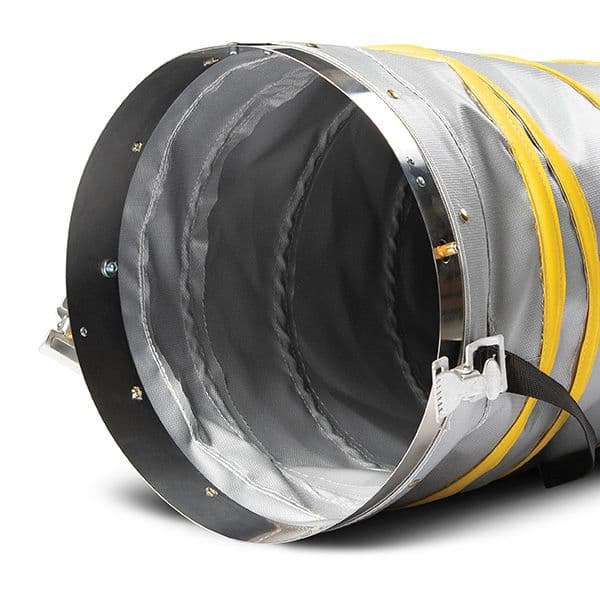

Portable ducts typically look like large, cylindrical, and flexible hoses giving them a snake-like appearance. Fabrics such as polyester, fiberglass, or even PVC are used in manufacturing.

Some portable temporary ducting have sophisticated designs with high-end collar or joint networks that connect to various industrial heating, cooling, or fan units.

Another common feature is a spiral pattern along the duct. This "spiral" is a wire coil that serves as the duct's skeleton throughout its length to keep the shape and prevent ducts from collapsing. Portable ducting is often used in commercial job sites, and some may even be a part of a permanent ductwork installation.

Is layflat ducting a form of portable ducting?

There are other types of portable temporary ducts that can be much more basic in their construction. Some can be clear poly-material on a roll without a wire structure or collar joint.

While these "layflat ducts" wouldn't be recommended for heavy-duty heating or cooling applications, it's an affordable, customizable option cut to a given length and punctured where desired for air distribution.

Layflat ducts are seen on smaller-scale job sites or even in remediation work where drying, dehumidification or ventilation are required and a more expensive duct may be considered overkill.

Advantages of Portable Temporary Ducting

As we've discussed, the importance of air quality is two-fold. One crucial aspect is promoting circulation, which entails pumping fresh air into a room, removing contaminants and preventing "stuffiness." The second is temperature control when a heater or air conditioner raises or lowers the temperature of a designated space, respectively.

Good ventilation is imperative to remove contaminants, such as pollutants, bacteria, moisture, and unpleasant odors. Construction projects can also have contaminants such as metal/wood shavings, mineral residues, and other general construction or manufacturing by-products.

Certain types of work, like welding, require ventilation to remove hazardous fumes and toxic gasses emitted from heated metals. A welder in the field can use a portable temporary duct with a fan or blower unit to capture these glasses and keep their workspace clear and safe, especially if the work is enclosed.

As projects progress, demands for warm or cool air may shift depending on the season and the local climate. Working on an outdoor site in July will carry different environmental hazards than working on that site in December. Therefore, it's crucial to maintain air quality and adjust temperature as the weather changes.

In many circumstances, portable temporary ducting is optimal as it easily flexes and adapts around jobsite obstacles.

HVAC: A Synonym for Air Quality

If you've ever experienced work in a stuffy area with poor ventilation, you've likely experienced chills, overheating, unpleasant odors, or even triggered allergies.

The frustration from unsafe work conditions can compound without adequate fresh air delivery. HVAC technology provides the solution by regulating temperature, humidity, and air purity so personnel can stay focused and on task. It's safe to say that no one wants to breathe polluted air. That might be an understatement, but what isn't overstated is the role HVAC plays in keeping optimal air quality indoors.

Installing internal HVAC units is critical to circulate and filter our air. However, permanent mechanical units usually come after the framing and general construction. Before permanent installations, temperature and air quality control must come from an alternative source for work crews or other personnel in the area.

Portable Temporary Ducting under the HVAC umbrella

This is where portable temporary ducting comes into play.

As we know, portable ducts are used with HVAC units that provide heating or cooling to improve working conditions and air quality. We also discussed how portable temporary ducts circulate the air throughout a structure when a permanent duct installation isn’t present or available to do so.

However, these resources aren't exclusive to construction projects. Let's say the military is setting up a hospital tent in the field that needs proper ventilation for a medical space, or perhaps a large tent or marquee is set up for a wedding reception or a concert in a park.

Unfortunately, there's no permanent ductwork that you can hook up to in these situations, and most rental tents don't come with built-in HVAC units. Most organizations or event groups that utilize these temporary structures will buy/rent portable air conditioning (AC) or heater units to control temperature and air quality.

A network of portable temporary ducting will come with these units to serve as the channels for the fresh air to be pumped through, providing much needed airflow to the space where none would exist otherwise.

Types of Portable Temporary Ducting

So far, you might have put it together that portable temporary ducting boils down essentially to three different categories through the HVAC umbrella. These systems comprise heating, ventilation, and AC, so portable temporary ducting must accommodate all three.

Let’s break down these situations to get to the nitty-gritty of each type.

Heating

Put yourself in the work boots of someone walking into a construction site of a brand new home. The concrete foundation is poured and the framing is coming together, but construction is still far from over. The structure is not relatively insulated from the outside, and it also happens to be the dead of winter in northern Minnesota. The temperature is frigid at -22°F (-30°C) with wind.

Sounds fun, right?

The building may have hoarding tarps over exposed windows and door openings, but the cold air is still heavy in all the rooms. These work conditions will be difficult for even the most seasoned construction worker.

However, there's some good news! Your company rents an industrial HVAC unit for heating, and it shows up on a trailer just before you are going to run and sit in the truck to warm up.

You unfurl the ducting that came with it and attach one end to the unit and then bring the other to the window of the room you're working in. The HVAC heater switches on and you feel the rush of hot air around you. Before long, you forget all about how cold it was just minutes ago.

That's the benefit of portable heat ducting. These ducts are insulated, fire-resistant (FR), and can typically be used in horizontal and vertical orientations if you're on a different floor than the heat source. The ducting effectively raises the ambient air temperature to provide a comfortable workspace for personnel and prevents equipment from freezing when you face bitter weather.

Portable temporary heat ducting also delivers the added benefit of ventilating the space by circulating new air through a supply duct and returning exhausted air to recycle at the HVAC unit.

Why should heat ducts be insulated?

Various materials like neoprene, polyurethane, polyethylene, or even fiberglass make up a lot of portable heat ducts. Heat-resistant coatings can adorn these materials to withstand the high temperatures of concentrated hot air pushed through by the HVAC unit.

However, there's a double benefit, which is preventing the heat escaping outside of the duct during transport. Leaks compromise efficiency and can lead to costing you more for less heat output.

Many portable temporary heat ducts available on the market have maximum temperature ratings ranging from 338°F - 500°F (170°C - 260°C), enabling them to operate efficiently with all manner of industrial-sized units that generate higher heat outputs.

Air Conditioning

Let's go back to the analogy of being a construction worker on a jobsite, but let's say you're now in the middle of summer in Phoenix, Arizona. Freezing cold temperatures aren't your problem anymore, and the temperature on the thermostat is sitting at a scorching 100°F (38°C).

Dehydration and overheating are possibilities in these conditions and are similarly unsafe to winter cold.

Again, let's say your company rents an HVAC unit, but this time it's specifically for AC. You hook up the ducting to the unit and bring the other end into the room you're working in. When the switch flips on, you're hit by a blast of refreshing cool air. At that moment, it's the greatest thing you could feel amidst the scorching heat.

Thank goodness for air conditioning.

Many construction companies rent portable air conditioner units, sometimes called spot coolers, to remedy such conditions. These units sit on trailers or in the workspace and can move around the site where AC is required.

Portable temporary ducting shines in these applications, following crews to cool them as they progress on the jobsite. A duct designed to handle AC can hook up the air conditioner and expand into the space needing to be chilled, just like the heating duct.

You can also place AC ducts horizontally or vertically if the cooling space is on a floor above or below the unit.

Is flexible AC ducting insulated and does it resist mold?

Like portable heat ducting, manufacturing AC ducts use insulated materials such as polyethylene (PE) and PVC fabrics. In addition to being flame-retardant, portable temporary AC or cooling ducting withstand all the rigors of heavy industrial use.

The duct fabric protects the cool air from external heat and exterior abrasion that may puncture the duct, causing air leaks. These materials also resist mold and mildew caused by condensation from the industrial cooling unit or other environmental factors.

Ventilation

As we discussed, some types of work, like welding, require ventilation to prevent the worker from breathing in toxic fumes. Other enclosed work areas, like sawmills, factories, or even general construction sites, can accumulate a massive amount of debris and contaminants.

By definition, ventilation introduces outdoor air into a space. Regardless of heating or cooling purposes, all portable temporary ducts provide ventilation by displacing indoor contaminants.

The wind is a natural source of ventilation in the world around us, and the aim of HVAC in terms of ventilation is to act as a form of synthetic wind. This is known as "mechanical ventilation," which is essentially a fan-driven flow of air from outside being pushed indoors.

Similarly, exhaust fans on HVAC units will draw air out of the building to create an equal flow in and out. Portable temporary ducting is the supply and return pathways that complete the airflow circuit from the HVAC unit to a designated space.

Circulation is an essential function for ventilation. For instance, a company might be doing a 2-day trade show in their large warehouse without permanent HVAC units present.

Usually, the warehouse is ventilated enough for the storage of products. Still, hundreds or potentially thousands of people crammed together emitting body heat with no airflow will make that warehouse too warm and stuffy.

To avoid vendors and patrons fanning themselves all day to create their own airflow, the company could rent a couple of HVAC units big enough to emit enough BTUs of fresh air for the warehouse. Hooking up portable temporary ducts will provide the pathways for the air to travel, and the circulation of supply and exhaust provides the proper ventilation needed to keep air quality optimal.

Duct Sizes & Features

Different sizes of portable temporary ducting are available to cater to different needs. Such ducting includes supply and return ducts.

Generally, return ducts are larger than supply ducts, as they must handle a larger volume of air rushing back to the HVAC unit. Supply ducts can usually be smaller, as they carry increased air pressure pushing into the space for circulation.

What’re some diameter details for portable ducting?

As stated, portable temporary ducting is round and comes in various diameters. Many manufacturers have a standard base diameter of about 8" and increase by 2" increments to 16" or even 24" diameters.

The reason for these "standard" sizes is to match up with current HVAC unit openings where the ducting is attached.

Custom duct diameters can also be made but usually come at a higher cost than standard sizes. Some custom sizes can be as small as 4" and get up to 25” and even larger.

Length options for portable ducts

Regarding length, most portable temporary ducting units come at least 8' or 10' long, with some of the standard ducts running up to 25' or even 30'.

Custom options are also available for portable temporary ducting. However, if you need 50' of ducting to run from the HVAC unit to a space, a fairly common practice is using two standard 25' ducts and attaching them together.

Purchasing or renting two standard ducts would be worth it in this case as a 50’ custom duct would be much more expensive to produce.

Adapters

In some situations, you may need an adapter for portable temporary ducts. In permanent installations, a large central duct from the HVAC unit will branch into smaller ducts that go in different directions to specific areas.

(Norseman carries both heating and AC duct adapters)

Each smaller duct brings a different "load" of air to that specific location. Mechanical “switches” control how much airflow goes into a given space.

For portable temporary ducts, there is less equipment than in permanent ductwork, so adapters are utilized to regulate flow. These are made of similar fabrics to the ducts, providing the same insulated or abrasion-resistant properties to maintain duct integrity and promote good airflow. Some examples of adapters include:

Wye or "T" Adapters These take air flow from one duct and split it into two directions. These two “branches” can be two smaller ducts, or even two ducts of the same size. Note: It’s essential to be sure the HVAC unit you're using can supply enough air output for both areas being serviced.

Elbow Adapters These adapters curve a duct around a bend at 90° or 45°. Some manufacturers can make custom-angled elbow adapters too. Most ducting can flex to go around most positions, but these adapters eliminate any possibility of the duct kinking or collapsing from bending it.

Reducers/Enlargers Reducers and enlargers change the diameter of a duct. You would use these to either increase or decrease the air pressure in the duct, or simply if two different diameter ducts needed to connect somehow.

End Caps These are closed fabric caps that effectively end a run of ducting. Some diffusion or ventilation ducts will use these caps to force air out through diffusion holes that run the length of the duct.

What is the “two-foot” duct rule?

When air pushes against the interior sides of the ducting it builds something called static pressure. This helps promote air velocity inside the duct.

Whenever there’s a change in airflow, for instance when an adapter is used, the rule is it takes 18-24” inches (or two feet) from that disruption before airflow ‘re-pressurizes’ and the air essentially “gets back up to speed.”

This is known as the “two-foot” rule in all manners of ducting, including portable ones. It’s important to consider this rule when using adapters or diffusion ducts, to try to keep airflow as strong as possible in the ducting network.

Collars

It's also crucial to understand collar configurations for portable temporary ducting. Collars are at the end of a duct and connect to the HVAC unit, adapter, or another duct or are left open-ended.

Finding a suitable collar that will work for the job is crucial. Examples of common collar types manufacturers make are:

Wire Collars These are usually the same type of wire in the skeletal helix for most portable ducts. The wire's encased in fabric, which provides rigidity. Primarily for duct-to-duct connection

Belt Collars These are a tapered excess flare of fabric from the duct that widens to fit around an HVAC unit port, an adapter, or another duct. Around the collar is a belt that cinches to tighten the collar with a spring buckle for release.

Band Collars A band collar is usually a solid metal band that attaches to the end of the duct material. These bands can have pins, buckles, or straps that can snap into fixed holes on HVAC units, other ducts, or adapters. Band collars provide a very snug fit and are used primarily in heating ducts.

Velcro Collars The end of a duct with this collar type has Velcro flaps that wrap around a connection point and stick to secure. These are on ducts for quick fastening, and the user controls how tightly they attach.

Buckle Collars Buckle collar assemblies consist of a ratchet and ridgid buckle system. The ratchet can be loosened so the duct can fit around an HVAC unit, another duct, or an adapter. The ratchet is cranked with the buckle to the desired tightness.

Pitch

The distance between the coils in portable temporary ducting is called the "pitch." Typically, the pitch is either 4" or 6", but ducts can be custom-built with a different pitch size.

The helix pitch is set so the fabric won't tear or wear through when the duct is dragged or rubbed along surfaces such as concrete or building walls. Supply ducting generally uses a 6" pitch, which has more distance between coils, while return ducting uses a 4" pitch, with loops spaced closer together.

Return ducts use a tighter pitch because they typically transport more air than supply ducts.

Horizontal and Vertical Applications

Generally, there's no distinction between ducts intended for horizontal or vertical use, as it's simply a matter of orientation. However, different types of portable temporary ducting may suit different directions better.

For example, air conditioning and ventilation ducting are usually hung vertically or installed horizontally overhead. Some ducts intended for this use have grommet tabs sewn every four feet to serve as an anchor point for suspension. You can use tie wire, zip ties, or other materials to secure the duct to a connecting point.

It's common to place heating ducts on the ground. They can still run horizontally or vertically to distribute heat, but most heat ducts don't have grommets as they're not usually hung up.

Hot air rises, so ducts are often left low in a space near the ground. An overhead orientation would be much less efficient at warming the workers and equipment below.

Final Thoughts on Portable Temporary Ducting

When you put it all together, portable temporary ducting is a highly efficient system for transporting air from an HVAC unit into a desired space or structure.

These ducts are durable and flexible, which allows them to deliver airflow efficiency that rivals permanent duct installations.

With a wide range of options available, there is a winning combination of portable temporary ducting to fit any HVAC project. Moreover, ducts can be fully customized to provide the specific airflow required for temporary or permanent structures.

Air quality is so vital to the safety of everyone in any given indoor structure, whether it’s under construction or completed. The air we breathe matters; ensuring good ventilation and temperature is paramount to health and progress.

Portable temporary ducting isn’t just one product but a wide range of products that adapt to your needs in any number of configurations to provide the necessary solution.

Which part of this guide helped you in your search? Did you learn anything new regarding portable temporary ducting or HVAC technology?

Use this guide and our other articles as a resource to help you determine which product is right for you and keep your projects efficient and working with you.

Share this